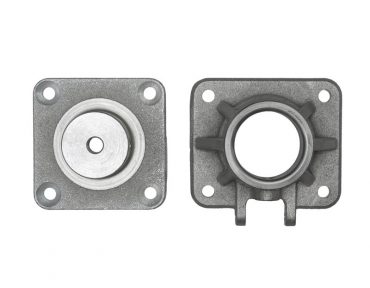

Die casting uses moulds to create often complex shapes in a range of metals. As it has lower tooling costs it’s more cost effective for lower production volumes than metal injection moulding.

Die casting is a way of producing complex metal shapes with high precision and with a smooth, accurate finish. Die cast products are of a higher quality than, for example, forged products, but are more expensive to make.

The choice between die casting and metal injection moulding often depends on what materials you need to use. Die casting tends to use materials with lower melting points such as zinc or aluminium and steel alloys.

The cost of making the mould is lower than for metal injection moulding, making die casting more suitable for lower volumes. However, we charge very competitive tooling costs whatever process you use.

Why choose die casting with us?

- Cost effective for small production runs of complex products.

- High precision finish.

- Small to medium sized metal components up to 4kg.

- Ideal for complex shapes, including multi-cavity.

- Multi-part assemblies and sub assemblies.

- Alloys including zinc, aluminium, magnesium and steel alloys.

- Range of secondary and finishing processes including CNC machining, turning, coatings, sand blasting, heat treatment, surface coating and plating.

- 500 piece minimum order quantity.

- Typical lead time 10-12 weeks following sample approval.

Example industry sector experience

Aerospace / Automotive / Construction / Chemical / Marine / Machine building / Defence / Oil and Gas / Catering