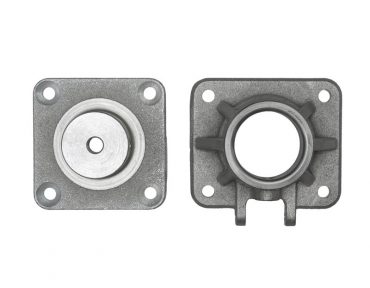

CNC machines – or computer numerical controlled machines – are sophisticated metal working tools that can drill, cut and mill metal into complex shapes, with extreme accuracy. It’s good for complex parts, but carries a higher price per piece.

CNC machining is the ideal process for producing small numbers of very complex components or products. It’s highly precise and accurate, with the ability to create complicated 3D shapes. The process, being computer controlled, is also perfectly repeatable.

CNC machining can use a very large range of materials, including most metals, composite materials, ceramics and some plastics.

This manufacturing process tends to be a relatively expensive choice, but Rencol Manufacturing is very competitive on price and we offer the benefit of decades of experience. We know when it’s best to use CNC machining on a job, and we’ll recommend another process if we think that’s best.

Why choose CNC machining with us?

- Produces complex 3D objects.

- High precision.

- Low to medium volumes.

- Part size – for turning max 300mm ø x 400mm long, machining max 600 x 400mm.

- A wide range of materials including all steel alloys, aluminium, brass and zinc alloys.

- A range of secondary and finishing processes. 250 piece minimum order quantity.

- Typical lead time 10-12 weeks following sample approval.

Example industry sector experience

Aerospace / Automotive / Construction / Cabinet building / Electronics / Furniture making / Marine / Machine building / Defence / Oil and Gas / Catering / Consumer goods