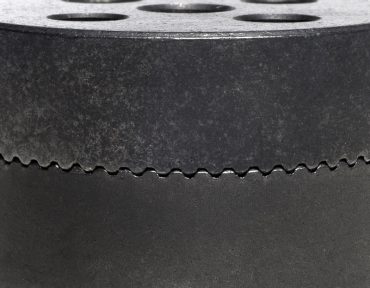

Metal injection moulding makes it possible to produce complicated shapes at high volumes, using a powdered metal mixed with a binder. The resulting product has similar strength to a metal alloy product, yet is faster to make.

Metal injection moulding is a good choice when you need to make large numbers of metal products, particularly smaller and more complex ones. The cost is mainly incurred in tooling the mould, which is more expensive than for casting or plastic injection moulding.

However, the production process is fast and cost effective, with minimal waste of materials, and the end results are precise and tough. The moulded products need little if any finishing.

We offer exceptionally competitive mould tooling costs, and a wealth of tooling and manufacturing experience.

Why choose metal injection moulding with us?

- Cost effective for larger runs of complex products.

- High precision finish.

- Small to medium sized metal components.

- Ideal for complex shapes, including multi-cavity.

- Multi-part assemblies and sub assemblies.

- Steel, stainless steel or aluminium.

- Secondary processes including heat treatment, surface coating and plating.

- 10,000 piece minimum order quantity.

- Typical lead time 10-12 weeks following sample approval.

Example industry sector experience

Aerospace / Automotive / Chemical / Medical / Defence / Security hardware